What is the Best Frozen Food Shipping Box for Your Needs?

In recent years, the demand for frozen food has soared. According to a report by Grand View Research, the global frozen food market is expected to reach $500 billion by 2025. This growth highlights the significance of efficient transportation solutions. Choosing the right frozen food shipping boxes is crucial for maintaining product quality.

Frozen food shipping boxes must provide insulation to prevent spoilage. The right packaging materials can keep items at safe temperatures during transit. For instance, insulated boxes with dry ice or gel packs ensure that perishable items remain frozen. However, many consumers may overlook the importance of box specifications.

Consider the sustainability aspect too. A study by the Food and Agriculture Organization indicates that food waste accounts for 1.3 billion tons annually. This adds pressure on suppliers to select eco-friendly frozen food shipping boxes. The challenge lies in balancing insulation performance with environmental impact. Exploring the best options requires careful evaluation of various products on the market.

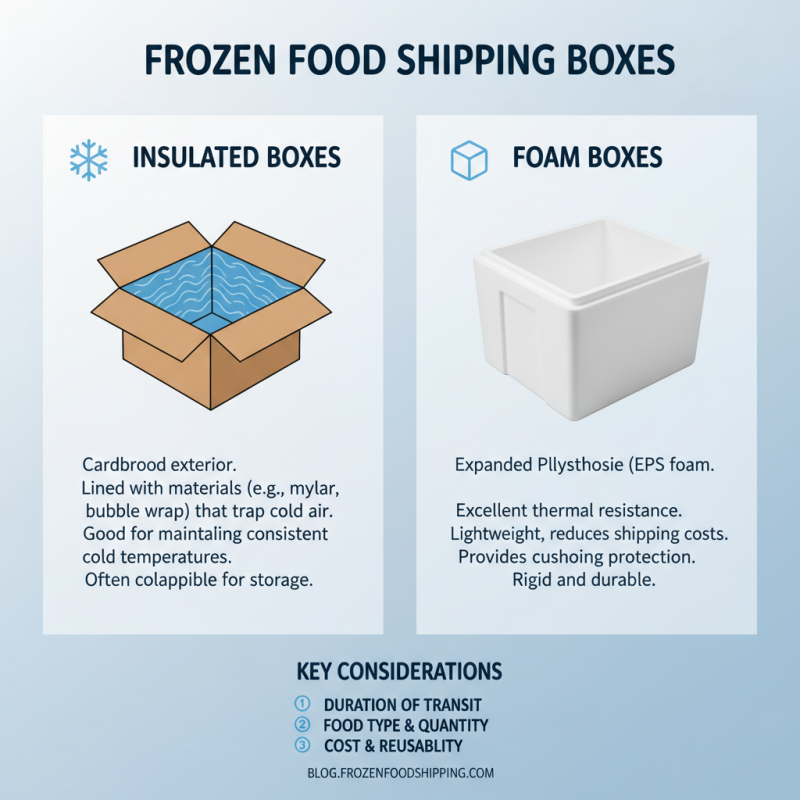

Types of Frozen Food Shipping Boxes Available in the Market

When selecting a frozen food shipping box, consider various types available in the market. Insulated boxes are popular for their ability to keep food cold. They are lined with materials that trap the cold air inside. Another option is foam boxes, which provide excellent insulation and protection from temperature changes. These boxes are lightweight, making them ideal for shipping.

Tips: Check the insulation material before purchasing. Not all insulations are equal, and some may not keep your food cold long enough.

Also, consider the size of your items. Boxes come in various dimensions, from small to large. If you choose a box that's too big, it might not maintain the right temperature. However, choosing a small box could lead to crushed items during shipping.

Some boxes even include dry ice options to help keep food frozen. Always confirm if your shipping provider allows dry ice. This can be a bit tricky and might require extra precautions. Keep these aspects in mind when selecting your shipping solution.

Factors to Consider When Choosing a Frozen Food Shipping Box

When selecting a frozen food shipping box, several factors come into play. Temperature retention is crucial. Materials must insulate effectively against heat. Many boxes use foam or cardboard with special liners. This retains cold while preventing melting. The size of the box is also important. It should fit the items snugly. Too much space can invite air, which impacts temperature.

Consider the durability of the box. It should withstand long shipping times and rough handling. A flimsy box may lead to leaks or tears. Think about the packing process too. It should be easy to load and seal. Complicated boxes can lead to mistakes, causing spoilage. Remember to weigh cost against quality. Cheaper options might save money but could lead to higher losses.

Finally, think about the environmental impact. Some boxes are recyclable or biodegradable. Using eco-friendly materials can be a responsible choice. It may not always be the cheapest option. Reflect on whether saving a few dollars is worth potential quality and waste issues. Finding the right balance is key.

Comparison of Insulation Materials for Frozen Food Shipping

When shipping frozen food, insulation materials play a crucial role.

Proper insulation ensures temperature control during transit. Common materials include

Styrofoam, fiberglass, and recyclable options.

According to industry data, Styrofoam offers the highest insulation efficiency.

It retains the coldest temperatures for longer periods, which is essential for perishable items.

Fiberglass is another option, but it can be less effective due to its density. It may not sufficiently protect against external temperature changes.

Recyclable materials, while eco-friendly, often lack the same insulating properties as Styrofoam.

A study shows that over 70% of shippers prefer Styrofoam for its superior performance.

However, it raises concerns about environmental impact and disposal procedures.

Tips for selecting the right shipping box include:

- Testing the insulation material before shipping.

- Check for any gaps in the packaging. These can lead to significant temperature loss.

- Look for innovative insulation solutions that balance performance with sustainability.

Testing is the best way to avoid costly losses during transport. Poor insulation choices can damage shipping contents and impact customer satisfaction.

Cost Considerations for Frozen Food Shipping Solutions

When shipping frozen food, cost is a critical factor. Using the right shipping box can significantly affect total expenses. Insulated containers and gel packs are essential for maintaining temperature. Prices vary widely depending on materials and size. Evaluate your specific needs carefully. Sometimes, opting for cheaper boxes may lead to spoilage. That choice can cost more in the long run.

Shipping costs also depend on weight. Heavier packages incur higher fees. Consider how the box design affects that weight. It's easy to overlook details like added padding or excess insulation. These can inflate charges unexpectedly. Some businesses find themselves needing to adjust their strategies as they discover hidden costs.

Don't forget about bulk purchases. Ordering boxes in larger quantities can save money. Additionally, assess current suppliers for better deals. Prices can change frequently. As market trends evolve, so should your shipping strategy. Regularly review your shipping methods to identify inefficiencies. Reflect on your choices to ensure you're making the best decisions for your budget.

Best Practices for Packing Frozen Food for Shipping

When shipping frozen food, the right packing method is vital. Proper insulation is essential. Use insulated boxes to keep items cold. Dry ice or gel packs work well. However, it’s crucial to handle these materials carefully. Dry ice can be hazardous if not used properly.

Tips for packing:

- Always line the box with insulating materials.

- Place food securely to prevent movement.

- Avoid using too much packing material. This can reduce the insulation’s effectiveness.

- Monitor the outside temperature. Hot weather can compromise frozen goods more quickly.

Remember to label the package clearly. Indicate that the box contains perishable items. This helps ensure proper handling during transit. Also, review the shipping options. Choose a method that minimizes delays. Transit time is critical in preserving food quality.

Related Posts

-

Top Strategies for Selecting the Most Efficient Frozen Food Shipping Solutions

-

Solutions for Streamlined Frozen Food Shipping Boxes: Boosting Efficiency and Freshness

-

Chinese Manufacturing Elevates Global Standards Through Best Frozen Food Shipping Boxes

-

How to Choose the Best Frozen Food Shipping Boxes for Your Business Needs

-

7 Essential Tips for Optimal Frozen Food Packaging Solutions

-

Frozen Food Packaging Innovations Showcased at 2025 China 138th Canton Fair

中国

中国