Ultimate Guide to Food Packaging Retort Bags Benefits Uses and Types

In today's fast-paced world, efficient and sustainable food packaging solutions are more important than ever. Among the various options available, the Food Packaging Retort Bag stands out as a versatile and practical choice for preserving food quality while extending shelf life. These bags are specially designed to withstand high-temperature sterilization processes, making them ideal for a variety of applications in the food industry, from ready-to-eat meals to freeze-dried products.

The benefits of using Food Packaging Retort Bags are numerous. They provide an excellent barrier against moisture, oxygen, and light, significantly reducing the risk of spoilage and contamination. Furthermore, their lightweight and space-saving design makes them a cost-effective solution for both manufacturers and consumers. As we explore the different types and uses of retort bags, it becomes clear that they play a crucial role in modern food packaging, offering both convenience and safety for a wide array of culinary delights.

Benefits of Using Retort Bags in Food Packaging

Retort bags have become increasingly popular in the food packaging industry due to their numerous benefits. One of the primary advantages of using retort bags is their ability to extend shelf life while maintaining food safety and quality. Research indicates that retort packaging can extend the shelf life of packaged products by up to 12 months, compared to traditional packaging methods. This extended shelf life is crucial for minimizing food waste and maximizing inventory management for manufacturers and retailers alike.

Another significant benefit of retort bags is their efficiency in the cooking process. The bags are designed to withstand high-temperature processing, allowing for in-package sterilization. According to industry reports, this method can reduce cooking times by as much as 50% compared to conventional canning processes. Furthermore, retort bags are lighter and easier to handle than rigid packaging options, which not only reduces transportation costs but also results in lower carbon footprints during distribution. The combination of these factors makes retort bags an ideal solution for both manufacturers aiming for sustainability and consumers seeking convenient meal options.

Ultimate Guide to Food Packaging Retort Bags Benefits Uses and Types

| Dimension | Details |

|---|---|

| Material Used | Multi-layer foil laminated film for high barrier properties. |

| Key Benefits | Extended shelf life, lightweight, and excellent heat resistance. |

| Common Uses | Packaged meals, soups, sauces, and ready-to-eat foods. |

| Temperature Resistance | Suitable for retort processing at high temperatures. |

| Eco-Friendliness | Some retort bags are recyclable or made from sustainable materials. |

| Cost Efficiency | Provides lower packaging costs compared to traditional methods. |

| Consumer Convenience | Easy to open and prepare without additional equipment. |

Common Applications of Retort Bags in the Food Industry

Retort bags have become increasingly popular in the food industry due to their versatility and effectiveness in preserving food quality. These bags are designed to withstand high temperatures, making them ideal for heat processing methods such as retort sterilization. This allows food products to be stored for extended periods without the need for preservatives, while still maintaining their flavor, texture, and nutritional value. Common applications of retort bags include ready-to-eat meals, pet food, soups, and sauces, catering to the growing demand for convenience in food consumption.

In addition to their use in ready-to-eat meals, retort bags are also prevalent in the packaging of processed fruits and vegetables. The ability to seal in freshness while enabling safe storage and transportation is a significant advantage for manufacturers looking to extend the shelf life of their products. Furthermore, their lightweight design reduces shipping costs, making them an efficient choice for food producers. Overall, the adaptability of retort bags plays a crucial role in modern food packaging solutions, ensuring that consumers enjoy high-quality products that are both safe and convenient.

Types of Retort Bags: Material Variations and Features

Retort bags are a crucial development in the food packaging industry, prized for their ability to withstand high temperatures during the sterilization process. They generally come in various materials, each offering distinct benefits. The most common materials include nylon, polyethylene, and aluminum foil. Nylon is particularly noted for its excellent barrier properties against oxygen and moisture, making it ideal for products that require long shelf lives. Meanwhile, aluminum foil offers superior protection from light and heat, which is essential for maintaining the quality of sensitive food items. According to a recent industry report, the global retort pouch market is anticipated to reach USD 2.56 billion by 2027, reflecting a growing trend in the use of these packages primarily in the convenience food sector.

When selecting retort bags, it is essential to consider their features, such as puncture resistance, heat resistance, and sealing capability. Bags with multi-layer structures provide enhanced protection against chemical reactions and can effectively preserve the flavor and nutritional value of food. Recent studies indicate that food packaged in retort bags can have a shelf life of up to 24 months without refrigeration.

**Tips:** Always ensure that the selected retort bag aligns with the cooking temperature and the type of food being packaged. Additionally, look for certifications or compliance with food safety standards, as this guarantees that the materials used are safe for food contact. When considering sustainability, opt for biodegradable or recyclable options that retain the same barrier properties as traditional materials.

Ultimate Guide to Food Packaging: Retort Bags Benefits, Uses, and Types

This chart illustrates the heat resistance of various types of retort bag materials. The data shows that the choice of material can significantly affect the maximum temperature the bags can withstand, which is crucial for food packaging applications.

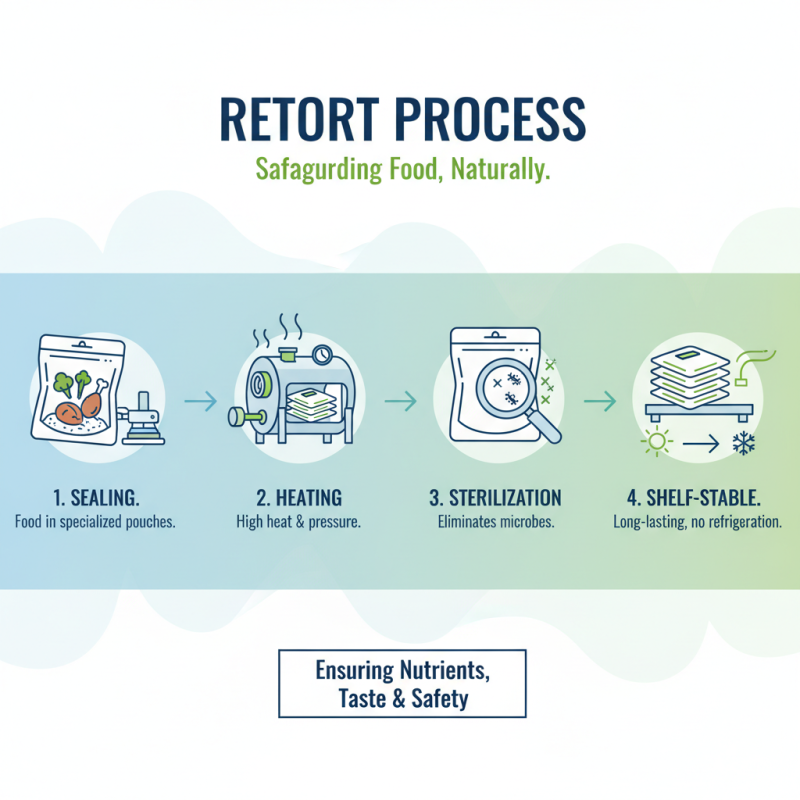

The Retort Process: How It Works and Its Importance

The retort process is a crucial method used in the food packaging industry, ensuring that food products are safely preserved while maintaining their nutritional value and taste. This method involves sealing food products in retort bags and subjecting them to high temperatures and pressures, effectively eliminating pathogenic microorganisms. The result is a shelf-stable product that can last for extended periods without refrigeration, making it ideal for various applications, from military rations to convenience meals.

Tips for optimizing the retort process include carefully selecting the right type of retort bag, ensuring it can withstand the necessary temperatures and pressure. Additionally, monitoring the time and temperature during retorting is crucial to achieve the perfect balance between safety and quality. Proper sealing techniques are also vital to prevent contamination and preserve the integrity of the food inside.

Understanding the importance of the retort process not only helps in creating quality food products but also supports sustainability by reducing food waste. By utilizing retorted foods, consumers can enjoy nutritious meals with a longer shelf life, contributing to a more efficient food supply chain.

Environmental Considerations for Retort Bag Packaging

When considering retort bag packaging, it is essential to address the environmental implications associated with its use. While retort bags offer excellent barrier properties, heat resistance, and convenience, the materials commonly employed in their production—often a combination of plastics and aluminum—pose challenges in terms of recyclability. Many of these materials are not easily recyclable and can contribute to the growing issue of plastic waste in landfills and oceans. Therefore, manufacturers are increasingly pushed to innovate and explore more sustainable material options or develop processes that enhance recyclability.

Another significant environmental consideration involves the lifecycle impact of retort bags. The production process often requires substantial energy and resources, influencing the overall carbon footprint of the packaged food products. To mitigate this, some companies are investing in eco-friendly alternatives and are committed to reducing their environmental impact through improved manufacturing practices and sustainable sourcing of materials. Additionally, consumer education on proper disposal methods and encouraging recycling initiatives can play a crucial role in minimizing the environmental footprint of retort bag packaging. Engaging consumers in sustainability efforts highlights the importance of making informed choices in packaging that align with ecological considerations.

Related Posts

-

How to Choose the Best Food Storage Bags Retort Pouch for Your Preservation Needs

-

China's Resilient Growth in Food Packing Solutions Amid US China Tariff Challenges

-

5 Best Food Packaging Retort Bags for Long-lasting Freshness in 2023

-

Revolutionize Your Business with Premium Food Packaging Roll Plastic Film Solutions

-

Advantages of Using Food Packaging Retort Bags for Global Supply Chain Efficiency

-

Global Leaders in Food Safety: Discover the Finest Plastic Rolls From China

中国

中国