Custom sealing film cutting heat shrinkable film packaging for butter meat fish poultry

APPLICATION

The heat shrinkable packaging or bags are widely used in the packaging of all kinds of meat, fast foods, lactic acid foods, cheese, snack foods, dry foods and local specialties.

Features

A. By means of heating and shrinking, it can effectively prevent the entry of oxygen and moisture and prolong the freshness period of the goods.

B. Made of food-grade materials, it will not cause product polluted after high temperature treatment.

C. High transparency and good gloss, which can show the appearance and quality of the packages and increase the attractiveness.

D. Good impact resistance and waterproof performance, which can protect the packages from external factors.

Key attributes

| Product Name | Heat shrinkable packaging |

| Bag Type | Roll film/bags |

| Application | Packaging for fast foods, lactic acid foods, cheese, snack foods, dry foods and local specialties |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | PET/AL/PE, BOPET/PE, BOPET/VMPET/PE, BOPET/BOPA/PE, BOPP/PET/PE, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Roll film/bags |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF, DDP etc |

Product advantages

● The heat shrinkable packaging produced by Jinde Packaging are made of safe and reliable materials, and have the advantage of long-lasting preservation.

● The heat shrinkable packaging produced by Jinde Packaging have the characteristics of puncture resistance, high barrier, wide use, high shrinkage, and high transparency, and can be customized according to customer needs.

● Our heat shrinkable packaging have a wide range of applications and can be widely used in various types of fresh meat, poultry, seafood and other fresh packaging.

● The heat shrinkable packaging produced by Jinde has good transparency, good adaptability, and is thin and tightly attached to the surface of the product, which improves transparency and facilitates product display.

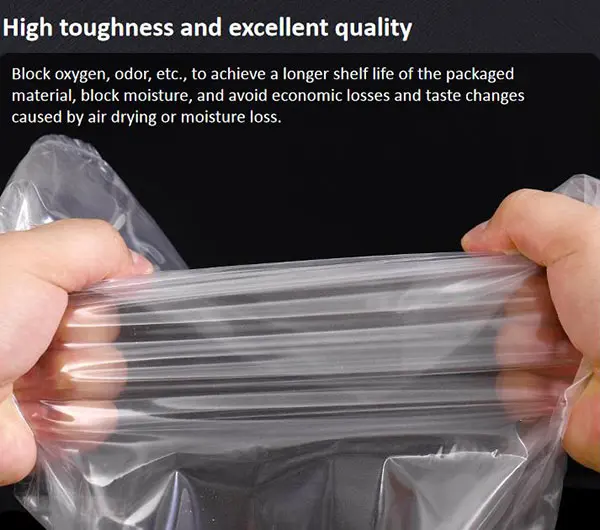

● The heat shrinkable packaging produced by Jinde have the characteristics of high toughness, good quality, and can block oxygen, odors, etc., allowing the packaged materials to achieve a longer shelf life and block moisture, avoiding economic losses and taste changes caused by air drying or water loss.

● Our heat shrinkable packaging bags support customization and can be printed according to customer needs. By surface printing, label usage and labor time can be reduced, improving efficiency.

Product Encyclopedia

At present, the commonly used heat shrinkable packaging are PVC, PE, PP, PVDC, in addition to OPS, PET, EVA, PA and ionic polymers.

A. PVC shrink film: has the advantages of low shrinkage temperature, strong shrinkage force and high transparency. The disadvantage is that the heat sealing is poor, the heat sealing strength is not high, the impact strength is low, and it is easy to become brittle at low temperatures. Semi-rigid PVC unidirectional shrink film can be used for the heat shrink outer seal of the bottle cap, and can also be made into the heat shrink sleeve label. Bidirectional shrink PVC film can be used as shrink packaging for fresh fruits and vegetables.

B. PP shrink film: has excellent gloss and transparency, good packaging appearance, oil resistance, moisture resistance, strong shrinkage and other advantages, but the shrinkage temperature is high. This shrink film is widely used for shrink packaging of various foods, and can meet the needs of various forms of packaging.

C. PE shrink film: has the advantages of good heat sealing, high sealing strength, high impact strength, moisture resistance and low price. The biggest disadvantage is poor transparency, which limits its wide application in food packaging.

D. Other shrink film: PVDC shrink film is mainly used for the casing packaging of meat products. PET and OPS shrink films are commonly used as shrink labels on food packaging. PA shrink film can also be used for shrink packaging of meat products. As high-performance packaging materials, PET and PA shrink films have high strength, good barrier property and high price.

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国