Custom Zipper Flat Bottom Pouch Food Nuts Storage Pouches Clear Self Sealing Packaging Bag

APPLICATION

Flat bottom packaging is a common packaging material for all kinds of powdered substances, such as coffee powder, flour, protein powder, medicine powder and so on. It can meet the packaging needs of different industries.

Features

A. Good sealing performance can effectively protect the powder from moisture, oxidation or deterioration. At the same time, it can also block the intrusion of gas, light and odor.

B. Good freshness properties to extend the freshness of the powder, to maintain its original flavor, texture and nutrients.

C. Takes up little space, easy to store and carry. In addition, the bags usually have a certain degree of tear resistance, not easy to break.

D. Some are equipped with venting holes, which can avoid the accumulation of gas during packaging, resulting in bag expansion.

Key attributes

| Product Name | Flat bottom packaging |

| Bag Type | Flat bottom pouch or customized |

| Application | Packaging for coffee powder, flour, protein powder, medicine powder |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | PET/PA/AL/SCPP, Matte BOPP/CPP, BOPET/AL/PE, BOPET/VMPET/PE, BOPET/AL/BOPA/PE, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Zipper top |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF, DDP etc |

Product advantages

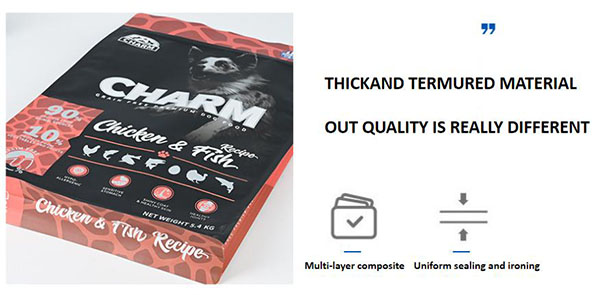

● The flat bottom packaging bags produced by Jinde Packaging are made of thick and multi-layer composite materials, with a rich texture and even sealing and ironing.

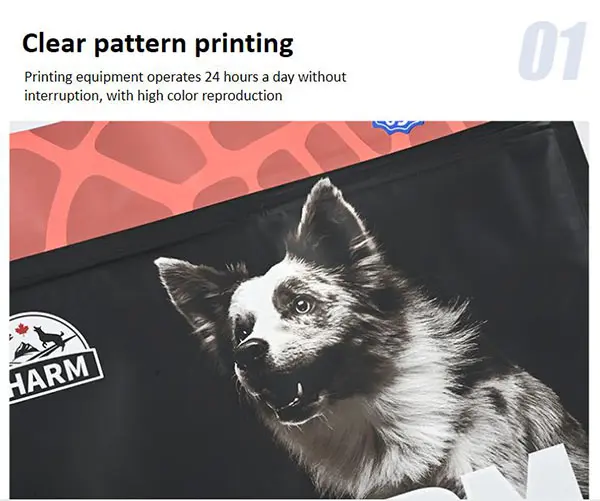

● Jinde Packaging's printing equipment operates 24 hours a day to ensure production efficiency, while providing you with high-quality flat-bottomed bag products with high color reproduction and clear pattern printing.

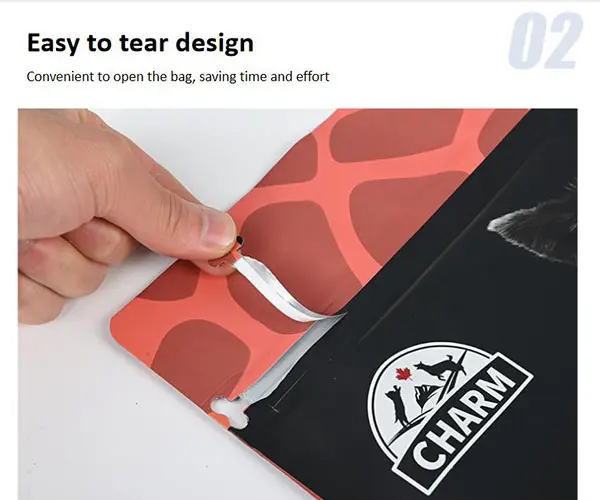

● The flat bottom bag of Jinde Packaging adopts an easy to tear design, making it easy to open the bag, saving time and effort.

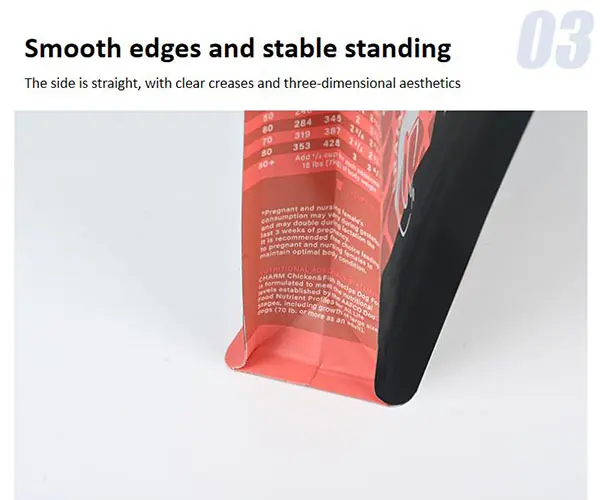

● The flat bottomed bags produced by Jinde Packaging have flat edges, stable standing, straight sides, clear creases, and three-dimensional aesthetics.

● Our flat bottomed bags have a thick bottom, good load-bearing capacity, tight seams, and are sturdy and leak proof, increasing the capacity of the flat bottomed bags.

Product Encyclopedia

The flat bottom pouch can also be designed to be narrower, thus potentially saving valuable shelf space. Due to its folding feature, it takes up less space than a stand-up bag. With flat bottoms and vertical side corner supports, these bags provide stability and attractive display on store shelves.

Coffee packaging: Professional coffee roasters prefer this type of packaging because of its premium appearance, filling and shipping efficiencies, and zippered pouches that are easy to open and seal to maintain freshness.

Food packaging: Flat bottom packaging is ideal for other food products such as rice, pet food and nutritional supplements, as well as food categories that want to differentiate themselves through quality visual appeal.

Non-food products: In addition to food products, flat bottom bags are also suitable for non-food products such as detergents, chemicals and cosmetics.

Customization: Flat bottom bags can be customized to meet specific product needs. Manufacturers can choose from a variety of materials, sizes and closure options to create packaging that matches their brand identity and product requirements.

Marketing: The flat bottom design of these bags offers five printable surfaces. This is advantageous for brands looking to display vivid graphics, product information and marketing messages to increase their visibility in stores.

Sustainability: Many of the flat bottom bags are environmentally friendly and made from recyclable or biodegradable materials.

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国