Double Fold Bottom Bag Beverage Bag-in-box Bag In Box For Wine/Water/Juice With Butterfly Valve

APPLICATION

Double Fold Bottom Bag is a kind of packaging bag with special design, which has two sockets at the bottom, which can be inserted into each other to form a solid bottom structure. Commonly used to store coffee, wine, juice, beer, champagne,water, and other beverages.

Features

A. Firm bottom structure, able to withstand heavier items, not easy to deform or rupture, to ensure the safety of the items.

B. The design of double-inserted bottom bag can disperse the weight and improve the overall load-bearing capacity, which is suitable for loading heavier items.

C. Made of lightweight material, it is lightweight and easy to carry. At the same time, its socket structure makes the bag can be stacked, taking up less space.

Key attributes

| Product Name | Double fold bottom bag |

| Bag Type | Double fold bottom bag |

| Application | Packaging for coffee, wine, juice, beer, champagne, water, and other beverages |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | PE/PA/AL, BOPET/AL/PE, BOPET/PE, BOPP/PE/CPP, BOPP/VMPET/LDPE, BOPP/PET/PE, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Handle top |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF |

Product advantages

● The double fold bottom bag produced by Jinde Packaging adopts a punching design device, which is more user-friendly and convenient for carrying.

● The double fold bottom bags produced by Jinde Packaging are made of materials that are tough and tear resistant. They are made of high-quality raw materials with good toughness, fearless of tearing, and resistant to tensile force.

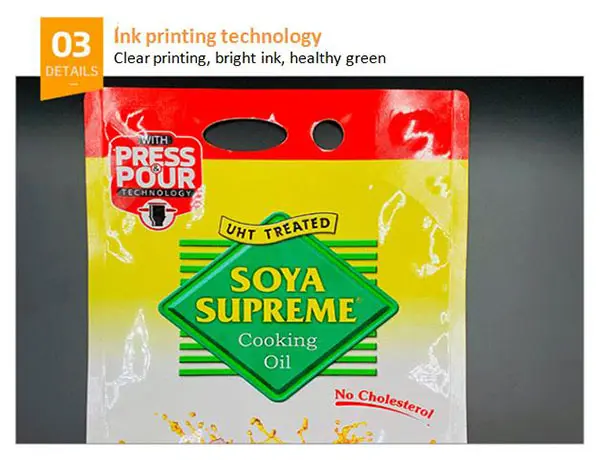

● The double fold bottom bag produced by Jinde Packaging adopts ink printing technology, which has clear printing, bright ink, and is healthy and green.

● The double fold bottom bags produced by Jinde Packaging have the characteristics of sealing, waterproofing, and large capacity. Our qualified film has strong load-bearing capacity, is wear-resistant, and is not easy to break.

Product Encyclopedia

Why is it said that double fold bottom bag/bag-in-box is a healthy and hygienic way of packaging?

1. The bag-in-box uses less packaging materials, only 20% material of the hard container, the packaging materials are easy to separate and recycle, and can be recycled, which is a recyclable environmentally friendly packaging.

2. The bag-in-box has small storage space before and after use, which reduces storage and logistics transportation costs as well as energy consumption.

3. Compared with the storage time of bottled products, the shelf life of packaged products in the bag-in-box is longer, which reduces the waste of products and saves resources.

4. The bag-in-box has a wide range of packaging capacities, from 1 liter to 220 liters, all can be supplied.

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国