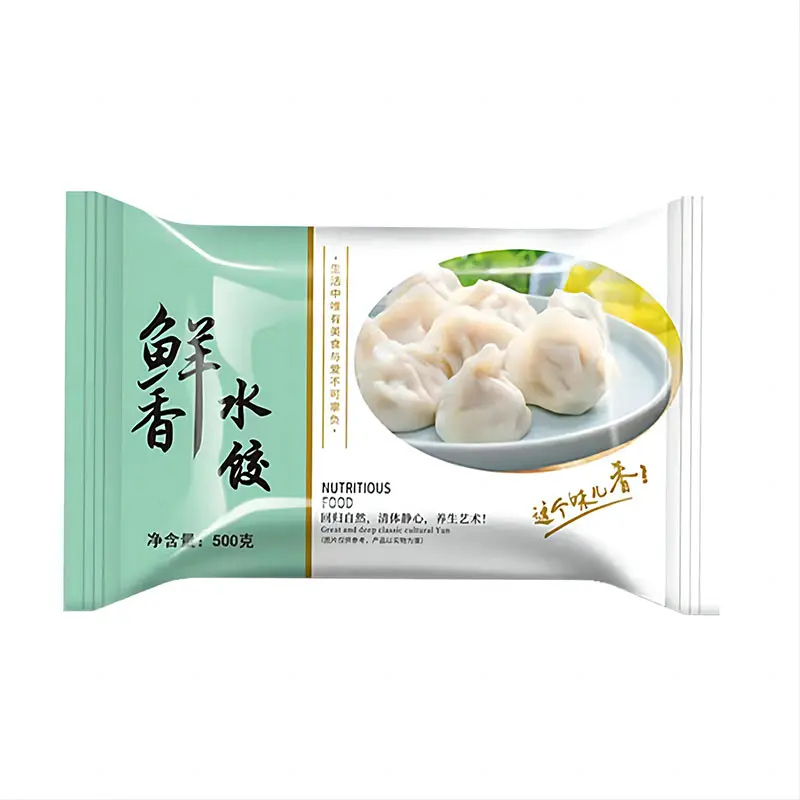

Factory custom seal plastic Frozen food packaging bags for beef meat fish packaging

APPLICATION

Frozen food packaging are commonly used to package foods such as frozen meats, fish, seafood, fruits, vegetables and frozen snacks. They are also commonly used to package frozen dough, ice cream, frozen soups, sauces and other prepared foods.

Features

A. Block the entry of air and moisture, thus prolonging the freshness of food.

B. Good sealing performance, can be easily sealed to prevent frozen food from contacting with the outside environment.

C. Transparent design, users can clearly see the food condition inside the bag, easy to choose and use.

D. Made of food-grade materials, it is harmless to the human body and also has a certain degree of degradability to reduce pollution to the environment.

Key attributes

| Product Name | Frozen food packaging |

| Bag Type | Stand-up pouch/flat bottom pouch or customized |

| Application | Packaging for frozen meats, fish, seafood, fruits, vegetables and frozen snacks or ice cream, frozen soups, sauces and other prepared foods. |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | PET/PE, PET/PA/PE, Matte BOPP/PET/PE, BOPET/AL/PE, BOPET/VMPET/PE, BOPET/BOPA/PE, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Zipper/Spout top/Plain |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF, DDP etc |

Product advantages

● The frozen packaging bags produced by Jinde Packaging use 100% brand new material , and the quality is not compromised, the raw materials are high-density PA+PE.

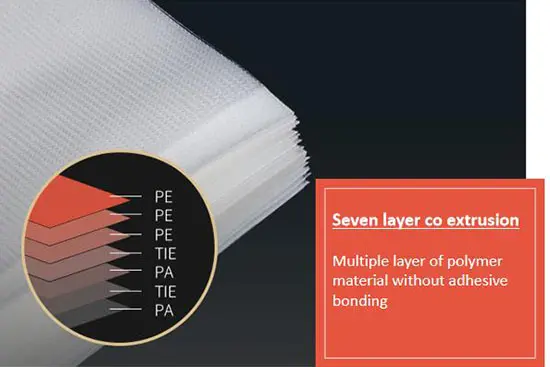

● The frozen packaging bags produced by Jinde Packaging are made of polymer materials that can be used for food, with seven layers of co extrusion, no glue bonding, and no packaging machine designated.

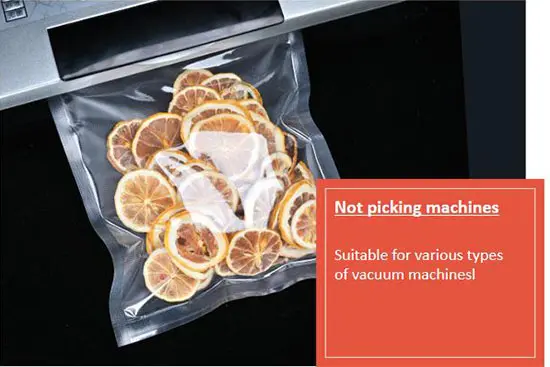

● The frozen packaging bags produced by Jinde Packaging are machine free and suitable for various types of vacuum machines.

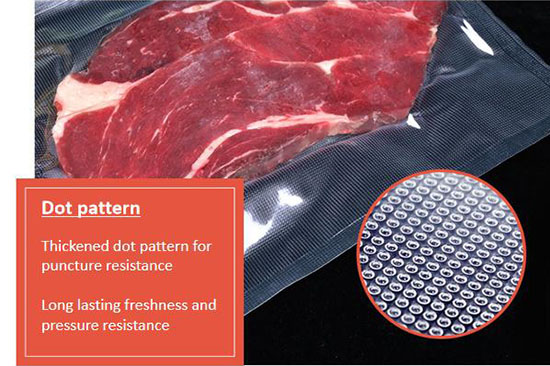

● The frozen packaging produced by Jinde Packaging adopts thickened dot patterns, which have the characteristics of puncture resistance, long-lasting preservation, and pressure resistance.

● The frozen packaging bags produced by Jinde Packaging can be refrigerated at low temperatures, can be frozen, and can withstand low temperatures of 150 ℃.

Product Encyclopedia

Frozen food packaging bags should meet the requirements of the large circulation, from production, transportation to sales, to maintain the quality characteristics of frozen products, to prevent the contamination of bacteria and harmful substances:

A. Low-temperature resistance: frozen food packaging bags should be able to maintain its structure and performance stability in low-temperature freezing conditions. In the low-temperature environment, the bags should not appear rupture, brittle phenomena to ensure that the food is not damaged in the freezing process.

B. Barrier properties: frozen food packaging bags should have excellent barrier properties, can effectively block the oxygen and moisture penetration into the bag. This helps to maintain the freshness and nutritional value of the food and extend the shelf life of the food.

C. Impact resistance: frozen food packaging bags should have good impact resistance, can withstand external impact and friction during transportation and sales. This helps to protect the food from damage and improve customer satisfaction.

D. Transparency: frozen food packaging bags should have a certain degree of transparency, can clearly show the quality and appearance of food. This helps customers to understand the variety, color and size of the food and other information to improve the willingness to buy.

E. Safety: Frozen food packaging bags should ensure the safety and hygiene of food. In the production process, relevant health standards and regulations should be followed to ensure that the bags are clean and sanitary.

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国