High Quality Food Grade Flexible Packaging PET CPP PE Plastic Laminated Film Roll

APPLICATION

Food flexible packaging is widely used in a variety of food industries, such as beverages, dairy products, snacks, frozen food and so on.

Features

A. Compared with traditional glass bottles or cans, food flexible packaging is lighter and more portable, convenient for consumers to carry and use.

B. Good sealing performance can effectively prevent food from air, moisture, light and other external factors, to extend the shelf life of food.

C. Flexible packaging usually has a good toughness, not easy to break, can protect the integrity and safety of food.

D. Transparent or semi-transparent material allows consumers to clearly see the food inside the package, improve the credibility of the purchase.

E. Personalized design can enhance the attractiveness of the product.

Key attributes

| Product Name | Food flexible packaging |

| Bag Type | Stand-up pouch/flat bottom pouch or customized |

| Application | Packaging for beverages, dairy products, snacks, frozen food |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | BOPP/VMCPP, BOPP/CPP, BOPET/PE, BOPET/VMPET/PE, BOPET/BOPA/PE, BOPP/PET/PE, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Zipper/Spout top |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF, DDP etc |

Product advantages

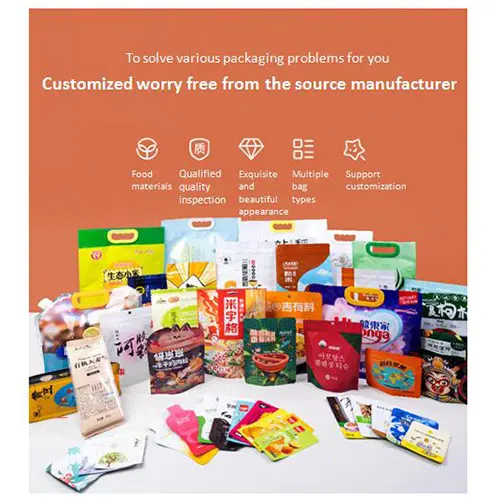

● Jinde Packaging is the direct manufacturer, with personalized customization, we solve various packaging problems for you. Our food flexible packaging is made of food-grade materials which boast qualified inspection, exquisite appearance, multiple bag shapes.

● The food flexible packaging produced by Jinde Packaging adopts multiple material composites with exquisite craftsmanship, rich experience, and strict quality control. The food flexible packaging we produce is solvent-free composite, ensuring pollution-free. The outer layer material is BOPP/matte BOPP/polyester PET/nylon PA, etc. The middle layer material is PET aluminum plated/kraft paper/ALl/white cardboard, etc. The inner layer material is PE/CPP/CPE.

● The quality of food flexible packaging produced by Jinde Packaging has been further upgraded, supporting high fidelity 10 color printing. More and more customers are choosing us for our expertise.

● The food flexible packaging produced by Jinde Packaging is designed by senior designers and provides customers with free design drawings.

● The food flexible packaging produced by Jinde Packaging ensures quality, quantity, and delivery. And urgent orders are scheduled day and night.

Product Encyclopedia

Flexible food packaging is a soft material used to package food, usually using laminated plastic film, aluminum foil, paper and other materials. It plays an important role in food preservation, moisture, oxidation, protect food quality and extend shelf life. Food flexible packaging products are widely used in all kinds of food industry, such as frozen food, instant food, beverages, dairy products, pastries, candy and so on.

Flexible food packaging has the following characteristics:

1. High plasticity: food flexible packaging can be customized according to the shape and size of the food, and can meet the packaging needs of different foods.

2. Excellent freshness: flexible food packaging can effectively prevent the intrusion of oxygen, water vapor and odor, thereby extending the shelf life of food.

3. Lightweight and easy to carry: compared with the traditional glass bottles, metal cans and other forms of packaging, flexible food packaging is more lightweight, easy to carry and storage.

4. Convenient way to open: flexible food packaging is usually used zipper, pull ring or pull line and other ways to open, more convenient for consumers to use and save.

5. Good visibility: because the flexible food packaging is made of transparent materials, consumers can visualize the food inside the package, improving the credibility of the purchase.

Flexible food packaging products mainly include the following types:

1. Plastic bags: plastic bags are one of the most common food flexible packaging products, the material is generally polyethylene (PE), polypropylene (PP), etc., with good sealing and transparency.

2. Aluminum foil bags: aluminum foil bags are usually made of aluminum foil and plastic composite materials, with good moisture-proof, anti-oxidation and heat insulation properties, suitable for coffee, tea, dried fruit and other food packaging.

3. Food packaging film: food packaging film is usually made of plastic film, widely used in frozen food, instant food packaging, etc., with good antibacterial and preservation of freshness.

4. Beverage packaging: beverage packaging is generally used in plastic bottles or aluminum cans and other materials, with good sealing and anti-corrosion properties, suitable for all kinds of beverage packaging.

Food flexible packaging products play an important role in the food industry. It can not only protect the freshness and quality of food, but also improve the market competitiveness and sales of food. With the improvement of people's awareness of food safety and environmental protection, food flexible packaging products are also constantly innovating and improving, towards a more environmentally friendly and sustainable direction.

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国