Multiple-layer co extruded vacuum packaging roll film for food packaging

APPLICATION

Vacuum packaging is widely used in the food industry to package meat products, seafood, dairy products, pre-made foods, nuts and dried fruits. It also has a place in the pharmaceutical, electronics, and cosmetic industries.

Features

A. Good oxygen barrier to inhibit the growth of microorganisms and molds, Preventing food and medicine from spoiling.

B. Customized according to the shape and size of the food, wrapping the food tightly, reducing the space inside the bag and improving the storage efficiency.

C. Effectively isolate water vapor in the air to prevent food from becoming moist or soft.

D. Insulates against dust and static electricity to avoid damage to electronics while providing better impact and shock protection.

Key attributes

Product Name |

Vacuum packaging roll film |

Bag Type |

Roll film/bags |

Application |

Packaging for meat , seafood, dairy products, pre-made foods, nuts and dried fruits |

Certificates |

ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

Surface Handling |

Gravure printing |

Material Structure |

PE, PP, PA, AL, PVC, or Customized |

Samples |

Free sample or negotiated without freight paid |

Sealing&Handle |

N/A |

Size |

Customized |

Color |

Up to 10 colors |

Thickness |

15-200 microns |

MOQ |

1000kg or per negotiation |

Production Flow |

Film blowing/casting/lamination |

Terms of Payment |

T/T, L/C or per negotiate |

Lead Time |

15-30 days or as per negotiated |

Incoterms |

EXW, FOB, CFR, CIF, DDP etc. |

Product advantages

■ Hubei Jinde Packaging Co., Ltd. is the source production factory that supports customization of various packaging products and provides high-quality product assurance.

● Original factory

● Customized

● Quality Assurance

■ The plastic shrinking Rolls produced by Jinde Packaging have advantages such as no air leakage, random machine packaging, and can be frozen.

● No air leakage

● Adapt to various machines

● Freezable

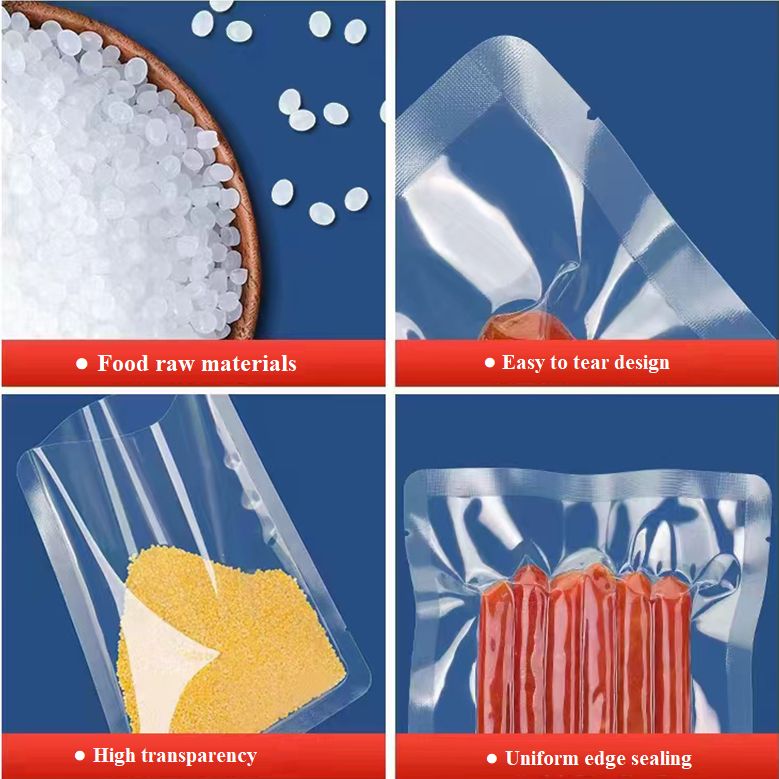

■ The plastic shrinking rolls we produce are all made of brand new food grade raw materials, allowing consumer to use them with more peace of mind

● High transparency preservation

● Food grade new raw materials are more reassuring

■ U-shaped easy to tear mouth, in line with humanized design, the product edge is neat and beautiful, and various product models and sizes are complete. Please contact us for customization

● Food raw materials

● Easy to tear design

● High transparency

● Uniform edge sealing

Product Encyclopedia

Food vacuum packaging bags refer to vacuum bags that come into direct contact with food and are used to contain and protect food. It has the power to prevent food spoilage, maintain its color, aroma, taste, and nutritional value. The performance of food vacuum packaging materials directly affects the storage life and taste changes of food. The selection of good packaging materials is the key to the success of vacuum packaging.

PE material: Generally, PE material is suitable for use in low temperature environments, so it is suitable for some seafood and other products that require preservation. Including food, vegetables, fruits, grains, etc. It can also be applied in other industries such as clothing, tape, film materials, and antioxidant.

RCPP material: suitable for cooking in high temperature environments. Generally used in the food industry, it can be widely used in packaging of meat, dairy, corn, soy products, etc. It has the characteristics of extending the shelf life and not spoiling.

PA material: Generally, PA material is added to vacuum packaging bags to increase physical strength and puncture resistance. It can be widely used in packaging materials with sharp edges, such as food with bones and other industries.

AL aluminum foil: This material is mainly used to increase barrier performance and shading, and is generally used in chemical raw materials. It can prevent moisture, light, and vacuum packaging, ensuring stable quality of chemical raw materials. Medical intermediates: Vacuum packaging can effectively extend the shelf life and prevent drug spoilage. Large precision mechanical equipment: can be moisture-proof, waterproof, and vacuum packaged to ensure stable quality of the equipment, as well as other products that require moisture-proof, waterproof, and vacuum packaging (potato chips, tea bags, etc.)

Water resistant PVA: This material is designed to increase barrier performance and form a high barrier coating. Widely used in packaging industries such as oilseeds, small grains, dried seafood, precious Chinese medicinal herbs, and tobacco.

PET material: has excellent physical and mechanical properties, creep resistance, fatigue resistance, friction resistance, and is not prone to deformation. Commonly used in food vacuum packaging, such as greasy foods, meat products, fried foods, etc. It is also commonly used as the outer layer material for steaming and cooking packaging, with good printing performance.

FAQ

1.Are you trading company or manufacturer?

We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

2.Do you provide samples ? Is it free or extra cost?

Yes, we could offer the sample. Free sample or negotiated without freight paid.

3.Do you have any MOQ limit for order?

Our MOQ is 10,000 square meters for films.

4.What information do you need to get a full quotation?

(1) Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

5.What makes you different in the packaging industry?

We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国