Customization process of food plastic packaging bags

Food plastic packaging is very common in our lives, but we are not very familiar with the customization process of plastic packaging bags. Today, we have summarized the customization process of plastic packaging bags and will take you to understand the steps of customizing food plastic packaging bags that we are not familiar with:

- Choose a custom manufacturer

Based on preliminary investigation, choose a plastic bag printing manufacturer with complete qualifications, rich experience, professional technology, and excellent service.

- Exploring design solutions based on the characteristics of food

Based on the characteristics of the packaged food, explore suitable packaging design schemes to make customers feel at ease and visually appealing.

- Final draft, plate making, and sample making

After the design scheme is finalized, it will be sent to the plate making company for plate making, which will take about a week. Print out a sample after plate making and provide it to the food company and packaging bag printing manufacturer for confirmation.

- Formal production

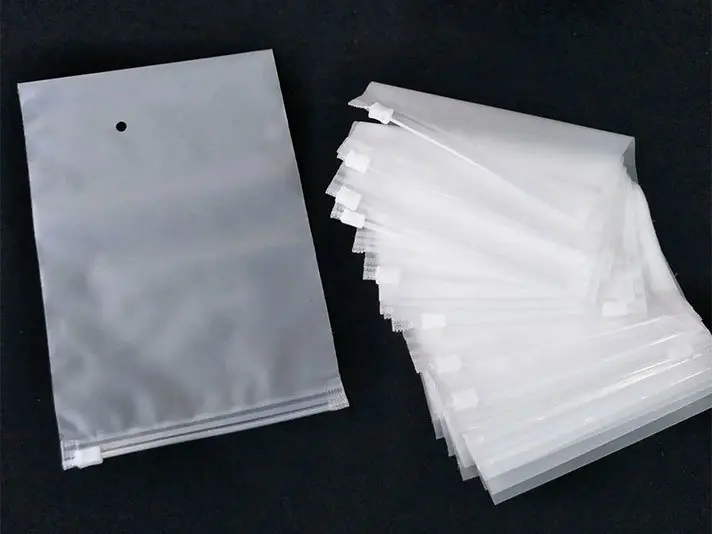

After the sample is confirmed, it will enter the formal production process. Through the operation of professional equipment such as printing, lamination, and bag making, the mass production of plastic packaging bags is completed.

- Inspection

After each batch of packaging bags is produced, they will undergo strict testing by inspectors to ensure that the products are of high quality and there are no inferior packaging bags.

- Package and ship

After the packaging bag inspection is completed, it can be packed neatly and sent to the food company!

During the operation of the above process, food companies should communicate more with packaging bag manufacturers! We guarantee to customize our own unique packaging bags.

中国

中国