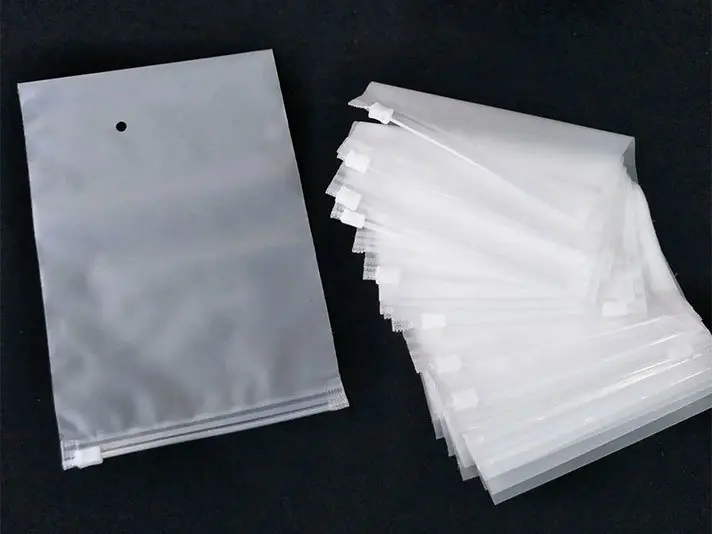

Detailed product introduction of soft nylon vacuum co extruded bag

Soft nylon vacuum co extrusion bag is a functional film material made by mixing nylon, PE and other raw material particles using multi-layer co extrusion technology. Soft nylon vacuum co extrusion bag can be used to package various fresh ingredients, such as meat, seafood, vegetables and fruits, as well as to package frozen foods to prevent dehydration and oxidation of food.

Soft nylon vacuum co extruded bag is a packaging material made using multi-layer co extrusion technology, which has excellent performance and a wide range of application fields. The following is a detailed introduction to soft nylon vacuum co extruded bags:

1、 Definition and Manufacturing Process

Definition: Soft nylon vacuum co extruded bag, also known as nylon co extruded vacuum bag or high barrier co extruded bag, is a functional film material made by co extruding raw material particles such as nylon and PE.

Production process: The production process of co extruded vacuum bags includes multiple steps such as raw material drying, vacuum feeding, extrusion, screen changing, melt pipeline distribution, mold casting, cooling and shaping, online thickness measurement, amplitude swing, traction cutting, dual station center winding, and finished product rewinding.

2、 Performance characteristics

High barrier properties: Soft nylon vacuum co extruded bags have excellent barrier properties, which can effectively block oxygen, water, carbon dioxide, odors, etc., thereby extending the shelf life of food and maintaining its freshness and nutrition.

Temperature resistance: This material can withstand high temperature cooking and low temperature freezing, and is suitable for packaging needs in different temperature environments.

Wear resistance and puncture resistance: The addition of nylon material improves the wear resistance and puncture resistance of the bag, making it more durable.

Environmental protection and safety: Soft nylon vacuum co extruded bags do not add adhesives, have no residual solvent pollution problems, are green, environmentally friendly, and safe and harmless.

3、 Application Fields

In the food industry, soft nylon vacuum co extruded bags can be used to package various fresh ingredients such as meat, seafood, vegetables, and fruits, as well as to package frozen foods to prevent dehydration and oxidation.

In the industrial field, this material is widely used for packaging and transportation of various products, especially for packaging thermal sensitive products such as electronic components and chemical products.

Other fields: In addition, soft nylon vacuum co extruded bags can also be used for packaging mechanical parts to protect them from contamination, corrosion, and oxidation.

4、 Precautions for use

Storage conditions: Soft nylon vacuum co extruded bags should be stored in a dry, cool, and away from direct sunlight to prevent accelerated material aging in humid or high-temperature environments.

Sealing temperature: Adjust the sealing temperature on the vacuum packaging machine between 180 ° C and 200 ° C to ensure a secure seal.

Avoid overloading: Use the bag according to its carrying capacity and avoid overloading to prevent breakage.

Regular inspection: Regularly check the integrity and sealing of the bag, promptly detect and repair any damage.

In summary, soft nylon vacuum co extruded bags have been widely used in the packaging industry, especially in the field of food packaging. With the increasing awareness of food safety and environmental protection among people, the market demand for this material continues to grow. In the future, soft nylon vacuum co extruded bags will develop towards a more environmentally friendly and intelligent direction. For example, by improving production processes and raw material formulations, the barrier and temperature resistance of bags can be enhanced; By introducing intelligent control systems and sensor technology, automation and intelligent control of the packaging process can be achieved.

中国

中国