How to choose fresh food vacuum packaging bags?

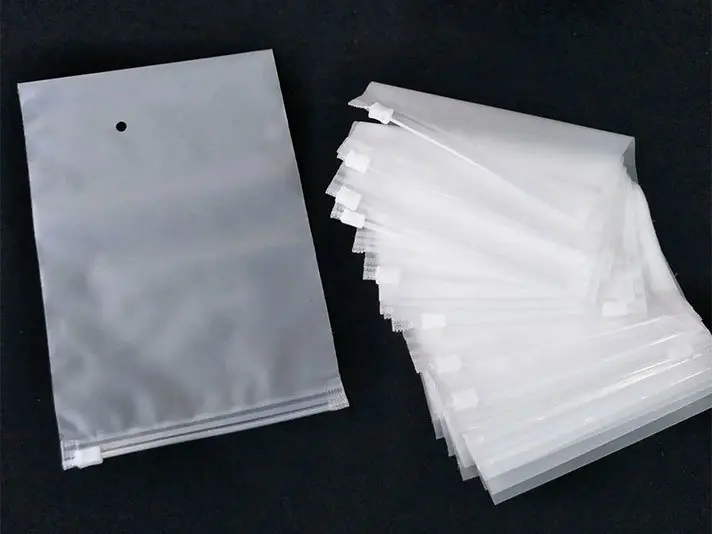

When choosing fresh food vacuum packaging bags, it is necessary to ensure that their materials meet food safety standards and have good anti oxidation, leak proof, and sealing properties. And according to the characteristics of different fresh foods, choose the appropriate size and shape to protect the food and extend its shelf life. Below, technicians from Jinde Packaging will provide a brief introduction to the selection criteria for different fresh food packaging bags:

1. Products with regular shapes or soft surfaces: For products with regular shapes or soft surfaces, such as sausage products, soy products, etc., their mechanical properties do not need to be high, only their barrier properties and sterilization temperature need to be considered. So, for this type of product, OPAVPE type is usually used. If high-temperature disinfection (above 100 ℃) is required, OPA/CPP structure or heat-resistant PE can be used.

2. Products with high surface hardness, such as products with bones, meat, etc., due to their high surface hardness and hard protrusions, are prone to puncturing the packaging bag during vacuum pumping and transportation. Therefore, their packaging requires good anti puncture and buffering capabilities, and can be made of materials such as PET/PAVPE, OPET/OPA/CPP, etc.

3. Perishable food: Low temperature meat and other perishable foods that require low-temperature sterilization do not require high packaging strength, but must have good barrier properties. Therefore, pure co extruded films such as PAIPE/EVOH/PA/PE, or PAVPE films or K-type coatings can be used. For products with high temperatures, PVDC shrink bags and dry composite bags can be used.

Jinde Packaging has been focusing on the research and production of food vacuum packaging bags for 11 years, and is a highly reputable food vacuum packaging bag manufacturer in the industry. We provide a one-stop service for food vacuum packaging bag design, printing, lamination, curing, slitting, bag making, quality inspection, finished products, and delivery, integrating production and sales. New material processing, high barrier, imported oil pressure for smooth edge pressing, high flatness, and good sealing. Obtained multiple certification qualifications such as FDA certification, ISO certification, SGS certification, MA product certification, etc., with a daily production capacity of over 500000 pieces, an annual output value of over 200 million yuan, and an annual sales volume of over 13000 tons. Manufacturer's source of goods, with the same quality and low price. Legitimate enterprises can issue value-added tax invoices. Winning the favor of numerous domestic and foreign customers. Service Hotline: 15902743510

中国

中国