How to choose vacuum food packaging bags? Introduction to the Material of Vacuum Compression Bags

When selecting vacuum food packaging bags, we should pay attention to the following aspects to ensure the safety and freshness of food:

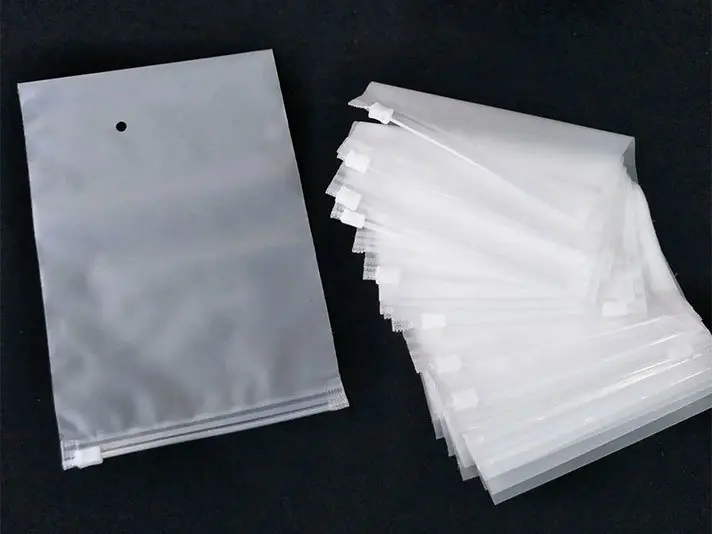

1、 Appearance and sealing: Observe the appearance of the packaging bag to ensure that its surface is smooth, wrinkle free, bubble free, and printed clearly with uniform color. Check if the seal is flat and ensure there is no air leakage.

2、 Material and thickness: Choose packaging bags made of food grade materials such as polyethylene (PE), polyvinyl chloride (PVC), etc. These materials are non-toxic, odorless, and can ensure the safety of food. Pay attention to the thickness of the packaging bag, as thicker materials usually provide better protection and extend the shelf life of food.

3、 Sealing test: Sealing is one of the important properties of vacuum packaging bags. When selecting, the sealing of the packaging bag can be tested by squeezing it forcefully or puncturing it with a needle. If air quickly enters or the pressure inside the bag rapidly increases, it indicates poor sealing performance.

4、 Barrier performance: Vacuum packaging bags need to have good barrier performance to prevent the penetration of oxygen and water vapor. Choose packaging bags that can effectively block external environmental influences to maintain the freshness and taste of food.

5、 Transparency: Packaging bags with high transparency allow consumers to clearly see the food inside the bag, making it easy to choose. Therefore, when choosing, priority should be given to packaging bags with higher transparency.

Introduction to the Material of Vacuum Compression Bags

There are many types of materials for vacuum compression bags, each with its unique characteristics and applicable scenarios:

1. Polyester (PET): colorless, transparent, glossy, with excellent mechanical properties, puncture resistance, friction resistance, high temperature and low temperature resistance. It is one of the commonly used composite vacuum bag substrates with barrier properties.

2. Nylon (PA): tough, transparent, excellent oxygen barrier, suitable for packaging hard items such as meat products, fried foods, etc.

3. Polyethylene (PE): has low transparency, but excellent gas barrier, oil barrier, and fragrance retention properties. It is relatively inexpensive and suitable for ordinary vacuum bag materials.

4. Aluminum foil: opaque, with good barrier and heat sealing properties, suitable for foods that require long-term storage.

中国

中国