How to use vacuum packaging bags?

Vacuum packaging bags can effectively function as oxygen and moisture barriers by utilizing the principle of deoxygenation. They are widely used in the market, and in order to fully utilize their functions, it is necessary to learn how to use them correctly. So, how to use vacuum packaging bags?

Jinde Packaging introduced that when it comes to the correct use of vacuum packaging bags, it is necessary to talk about the performance of the vacuum packaging bag material. For example, PE is suitable for low-temperature use, RCPP is suitable for high-temperature steaming and boiling use, PA is to increase physical strength and puncture resistance, AL aluminum foil is to increase barrier performance, light shielding, PET increases mechanical strength, and the shape is firm. EVOH has high barrier properties. Then, according to the requirements, various properties are combined, including transparent ones. To increase the barrier performance, a water-resistant PVA high barrier coating is used. The vacuum packaging bags applicable to different products are also different.

- Food high-temperature steaming bag

texture of material: NY / PE、NY / AL / RCPP、KNY / PE

- Food boiling bag

texture of material: PET / PE BOPA / PE PET / AL / PE

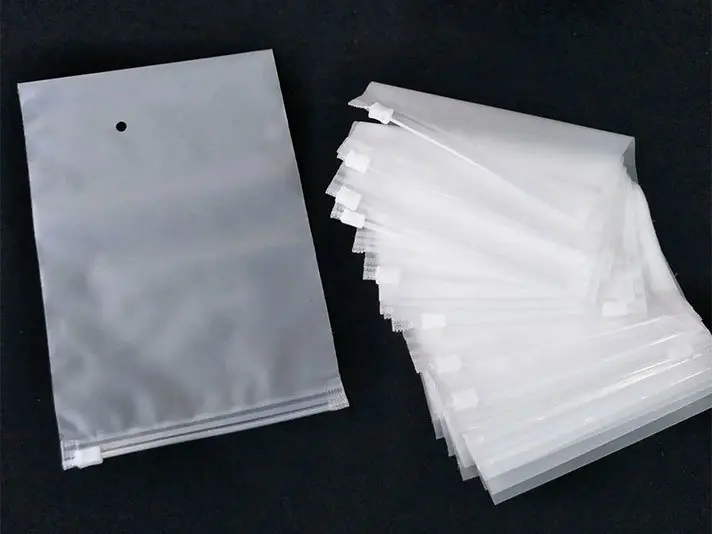

- Ordinary vacuum bag

Nylon co extruded film vacuum bag, nylon composite vacuum bag, PE vacuum bag

Vacuum packaging bags for electronic products

- Electronic vacuum composite bag

texture of material: NY/CPE, PET/NY/CPE, PET/CPP, PET/AL/NY/PE

The above introduction on the usage of vacuum packaging bags is organized by Jinde Packaging, which has years of industry experience and provides spot wholesale and small order customization services for vacuum packaging bags. Since its establishment, the sales volume has remained among the top. For more information, please follow the official website of Jinde Packaging.

中国

中国