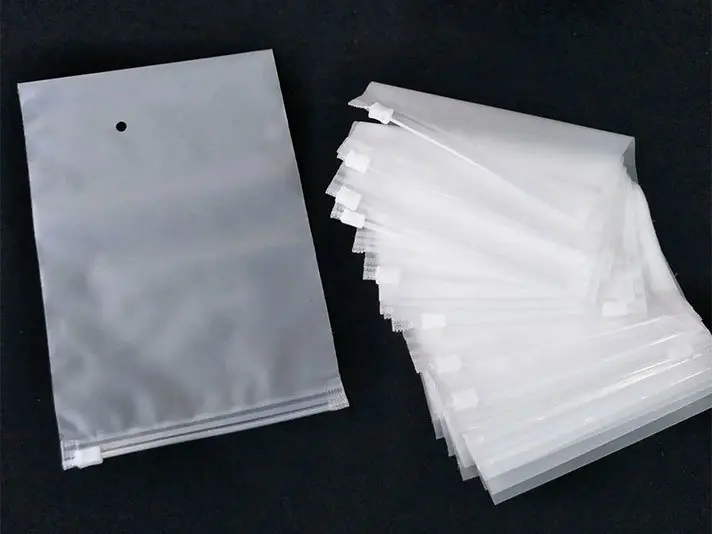

Precautions for using vacuum packaging bags

Vacuum packaging bags, also known as pressure reducing packaging, operate by placing the product in a well sealed packaging container, extracting air from the container to achieve a predetermined vacuum level, and then sealing it. This packaging method creates low oxygen conditions, making it impossible for microorganisms to survive, thus achieving the purpose of preservation and preservation. Its main purpose is to seal and package food, medicine, and other items, and to extract the air inside the packaging bag through suction, creating a negative pressure environment.

The precautions for using vacuum packaging bags mainly include the following points:

1、 Preparation and placement of items

Item drying:

Before placing items in vacuum packaging bags, ensure that they are clean and dry. Especially for food products, there should be no residual moisture, otherwise it may affect the preservation effect.

For clothing, bedding, etc., it is also necessary to ensure dryness to prevent residual moisture in the bag from condensing into small water droplets in low temperature environments, causing the bag wall to rupture.

Avoid sharp objects:

Check for sharp edges on the item to avoid puncturing the bag.

If the item has hard objects such as buttons or zippers, it should be folded or covered to avoid damaging the bag during the vacuuming process.

Item location:

When using a textured vacuum bag, be sure to place the food in the center of the bag to avoid contact with the bag wall, in order to prevent the food from moving during vacuum pumping and affecting the packaging effect.

2、 Sealing operation

Sealing force and time:

The control of sealing strength is crucial, too loose can easily cause air leakage, and too tight may damage the bag. It is recommended to apply slight pressure when sealing to ensure that the edges of the bag are tightly adhered and form a good seal.

The sealing time also needs to be controlled well, usually 3-5 seconds. If the time is too long, it may cause the bag to deform due to heat, and if it is too short, it may not seal tightly. Adjust the sealing time appropriately according to the material and thickness of the bag to achieve the desired effect.

Sealing inspection:

After vacuuming and sealing, carefully check whether the bag opening is tightly sealed. You can gently press the opening of the bag with your hand. If you feel any air leakage, you need to reseal it to ensure the preservation effect of the item.

3、 Vacuum pumping operation

Extraction continuity:

During the vacuum pumping process, there should be no pause in the pumping and continuous pumping is necessary, otherwise it may cause residual air.

Pump selection:

Choose the appropriate vacuum pump based on the size and quantity of the packaged items. For large items, it is recommended to choose manual or electric pumps because the compression force of automatic pumps is not high, which may cause excessive air residue when storing large items.

Extraction time:

The pumping time should be determined based on the size of the bag and the amount of items. Generally, a large bag needs to be pulled for 3 to 5 minutes before noticeable flattening occurs.

4、 Storage and Inspection

Storage conditions:

Vacuum packaging bags should be kept away from direct sunlight and high temperatures to prevent deformation or decreased sealing performance.

Regularly check the sealing to ensure long-term preservation effectiveness.

Sealing quality inspection:

Before storage, the sealing quality of the bag opening should be checked again, and continuous bubbles should be observed on the bag to determine if there is any air leakage.

5、 Other precautions

Bag cleaning:

Before closing the zipper, wipe off any fibers, dust, and other impurities from the sealed zipper part of the bag with water gauze to ensure sealing.

Bag damage handling:

If there are cracks or small openings in the vacuum packaging bag, you can use ordinary wide edge transparent tape to stick it on both sides and ensure a tight fit. However, it should be noted that severely damaged bags should be replaced in a timely manner to avoid affecting the packaging effect.

In summary, the precautions for using vacuum packaging bags involve item preparation, sealing operations, vacuuming operations, storage and inspection, and other aspects. Following these precautions can ensure the sealing performance and preservation effect of vacuum packaging bags, thereby extending the shelf life and service life of items.

中国

中国