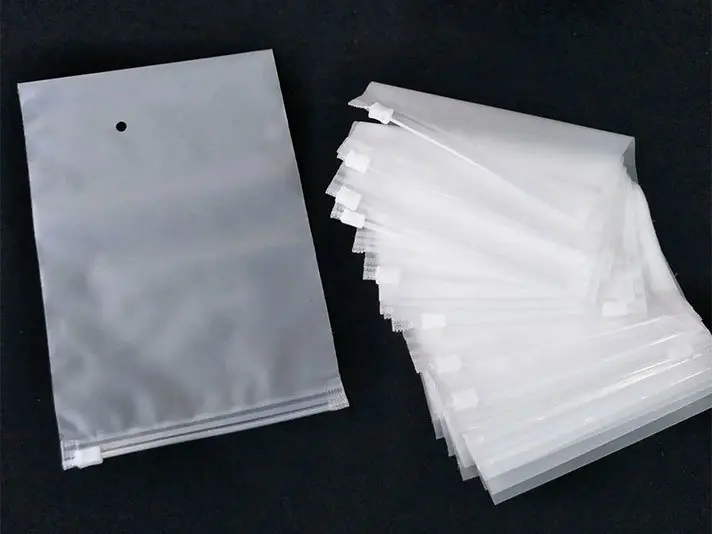

Production process of aluminum foil three edge sealed packaging bag

Aluminum foil three sided sealed packaging bag is a commonly used packaging material, which is widely used in the packaging of industries such as food, medicine, cosmetics, etc. due to its excellent barrier properties, moisture resistance, light shielding properties, and antioxidant properties. Aluminum foil three sided sealed packaging bags are widely used in multiple industries due to their performance characteristics. When using, attention should be paid to storage conditions, expiration dates, and waste disposal to ensure its performance and environmental friendliness.

The production process of aluminum foil three edge sealed packaging bags is a complex and delicate process that involves multiple steps and links to ensure the quality and performance of the product. The following are the detailed steps of the production process for aluminum foil three sided sealed packaging bags:

1、 Material selection and preparation

Aluminum foil selection: Choose aluminum foil materials with appropriate thickness and specifications according to packaging requirements. Aluminum foil usually has good barrier properties, light shielding properties, and oxidation resistance.

Plastic film selection: Choose plastic films that are composite with aluminum foil, such as polyethylene (PE), polypropylene (PP), etc. These films have good heat sealing properties and mechanical strength.

Printing material preparation: If you need to print patterns or text, you also need to prepare the corresponding printing ink and plate materials.

2、 Composite process

Glue coating: Apply an appropriate amount of adhesive on the contact surface between aluminum foil and plastic film to ensure that they can be firmly bonded together.

Composite: Aluminum foil coated with adhesive and plastic film are compounded by a laminating machine to form a composite material.

Maturity: The composite material is matured under fixed temperature and humidity conditions to fully cure the adhesive and improve the strength and stability of the composite material.

3、 Printing process

Plate making: Produce a printed version according to design requirements.

Printing: Apply printing ink evenly onto the printing surface of composite materials and print using a printing machine.

Drying: Dry the printed composite material to remove solvents and moisture from the ink and improve printing quality.

4、 Forming and cutting

Molding: Heating and stretching composite materials through a molding machine to form a packaging bag shape with three side seals.

Cutting: Cut the formed composite material according to the size requirements of the packaging bag to obtain individual packaging bags.

5、 Heat sealing process

Heat sealing equipment: Use a heat sealing machine to heat seal the three sides of the packaging bag.

Heat sealing temperature and time: Adjust the temperature and heat sealing time of the heat sealing machine according to the heat sealing performance of the composite material to ensure the firmness and sealing of the heat sealing.

Cooling: After heat sealing, the packaging bag is cooled to reinforce the strength of the heat seal.

6、 Inspection and Packaging

Appearance inspection: Check the appearance of the packaging bag for flatness, no damage, no printing errors, etc.

Performance testing: Testing the barrier, moisture, and light blocking properties of packaging bags to ensure compliance with design requirements.

Packaging and Storage: Pack and store qualified packaging bags for future use.

7、 Quality control

Throughout the entire production process, strict quality control is required for each link, including quality inspection of raw materials, control of composite quality, control of printing quality, precision control of forming and cutting, and control of heat sealing quality. Through strict quality control, the quality and performance of aluminum foil three edge sealed packaging bags can be ensured to meet the design requirements.

In summary, the production process of aluminum foil three edge sealed packaging bags is a complex and delicate process that requires strict control of the quality and performance of each link. Through reasonable production processes and strict quality control, high-quality aluminum foil three sided sealed packaging bags can be produced to meet various packaging needs.

中国

中国