Types and selection criteria of moisture-proof vacuum packaging bags

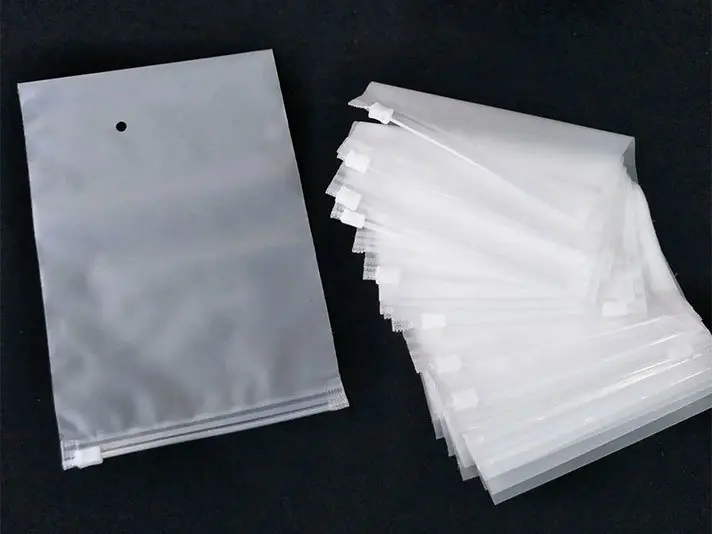

Moisture proof vacuum packaging bag is a special type of packaging bag mainly used to protect food, medicine, electronic products, and other items that are prone to moisture. Its design purpose is to effectively isolate moisture and oxygen, extend the shelf life of items, and maintain their quality through a combination of vacuum suction and moisture-proof materials.

There are many types of moisture-proof vacuum packaging bags, and the following are our common types of moisture-proof vacuum packaging bags:

1. Aluminum foil vacuum packaging bag: Utilizing the excellent barrier properties of aluminum foil, it effectively blocks the entry of air, light, and moisture, providing moisture resistance.

2. Nano moisture-proof packaging bag: Made of high-tech nanomaterials, it has strong barrier properties and moisture adsorption ability, which can effectively prevent moisture and preserve freshness.

3. Moisture absorbing and moisture-proof packaging bag: It contains moisture absorbing agents inside, which can absorb moisture from the surrounding air and provide moisture resistance.

4. Multi layer composite moisture-proof packaging bag: It is composed of multiple layers of films made of different materials, which not only have good barrier properties, but also can effectively prevent moisture.

These are common types of moisture-proof vacuum packaging bags, and the specific use depends on the items to be packaged and the usage environment.

Choosing a suitable moisture-proof vacuum packaging bag requires consideration of the following factors:

1. It is necessary to consider the characteristics of the packaged food and the required storage environment. For example, PE material can be used at low temperatures and is suitable for food choices that require freezing; RCPP material can be used for high-temperature steaming and is suitable for packaging cooked meat and food that requires high-temperature sterilization treatment.

2. Sealing performance: The sealing performance of moisture-proof vacuum packaging bags is very important, as it can ensure that air and moisture inside the packaging cannot enter the bag. Choosing bags with good sealing performance can maintain the freshness and quality of food and goods.

3. Tear resistance: Moisture resistant vacuum packaging bags need to have strong tear resistance to prevent accidental tearing of the packaging during transportation and storage.

4 Quality: The compression bag should be made of thicker, more resilient and elastic PA/PE compression bags, which are not much more expensive in cost, have good ductility, and are not prone to air leakage.

In summary, selecting a suitable moisture-proof vacuum packaging bag requires consideration of factors such as material selection, transparency, size and capacity, sealing performance, tear resistance, as well as quality and reliability. Before purchasing, you can consult the supplier for more details and suggestions to ensure that you choose a moisture-proof vacuum packaging bag that is suitable for your specific needs.

Jinde Packaging has been focusing on the research and production of vacuum packaging bags for 11 years, and is a highly reputable food vacuum packaging bag manufacturer in the industry. We provide a one-stop service for vacuum packaging bag design, printing, lamination, curing, slitting, bag making, quality inspection, finished products, and delivery, integrating production and sales. New material processing, high barrier, imported oil pressure for smooth edge pressing, high flatness, and good sealing. Obtained multiple certification qualifications such as FDA certification, ISO certification, SGS certification, MA product certification, etc., with a daily production capacity of over 500000 pieces, an annual output value of over 200 million yuan, and an annual sales volume of over 13000 tons. Manufacturer's source of goods, with the same quality and low price. Legitimate enterprises can issue value-added tax invoices. Winning the favor of numerous domestic and foreign customers. Service Hotline: 15902743510

中国

中国