What causes the vacuum packaging bag to become brittle after sealing?

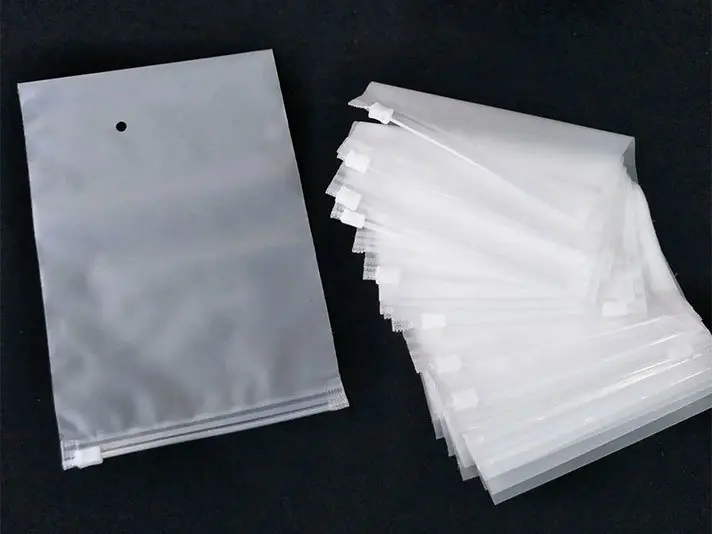

Vacuum packaging bag refers to a packaging method in which a product is placed in an airtight packaging container, the air inside the container is removed, and the sealed container is filled with a predetermined vacuum degree. Thus, it can be seen that the sealing performance of vacuum packaging bags is an important condition for their functionality. Whether the sealing of vacuum packaging bags is qualified directly affects the performance of vacuum packaging bags. So, what is the reason for the brittleness of vacuum packaging bags after sealing? Jinde Packaging will take you to a detailed understanding:

reason:

(1) The heat sealing temperature is too high.

(2) Excessive pressure.

(3) The heat sealing time is too long.

(4) The edge of the upper sealer is too sharp or the PTFE wrapped around it is damaged.

(5) The silicone rubber at the bottom seal is hard.

(6) During the compounding and curing process, a portion of the adhesive penetrates into the interior of the film. Due to the influence of adhesive penetration, the toughness (impact resistance) of the substrate decreases and the brittleness increases.

(7) After cooling and storage, the heat sealing strength of plastic composite packaging bags increases, but they also tend to become brittle.

resolvent:

(1) Select appropriate processing temperature, pressure, and heat sealing time based on the heat sealing characteristics of the inner sealing layer material.

(2) Check the surface condition of the upper heat seal to make the surface of the sealer flat.

(3) Wrap it with polytetrafluoroethylene cloth intact.

(4) Choose a silicone rubber pad with appropriate hardness.

The above reasons and treatment methods for the brittleness of vacuum packaging bags after sealing have been sorted out by Jinde Packaging. Jinde Packaging is a vacuum packaging bag manufacturer with more than 10 years of experience, providing one-stop services for vacuum packaging bag design, plate making, printing, lamination, and bag making. It also operates in bulk and customization, with synchronous online and offline operations, wide coverage, convenient communication, and favorable prices. Since its establishment, Jinde Packaging has consistently ranked among the top sellers and is an ideal manufacturer for wholesale and customization of textured vacuum packaging bags. Hotline: 15902743510

中国

中国