What is the process of "one item, one code" printing production?

The printing and production process of "one item, one code" is a carefully designed and executed process to ensure that each product has a unique identity identifier. The following are the detailed steps of the process:

1、 Design coding rules and label styles

Before starting printing, it is necessary to design coding rules, which usually include determining the size, format, and information content of the QR code, such as product name, production date, batch number, etc. At the same time, it is also necessary to design the style of the label to ensure that the appearance of the label is concise, clear, and easy to recognize.

2、 Generate a unique identifier code

Generate unique QR codes through specialized software or systems based on designed encoding rules. These QR codes will serve as identification for each product, ensuring that detailed information about the product can be traced back in subsequent processes.

3、 Printing preparation

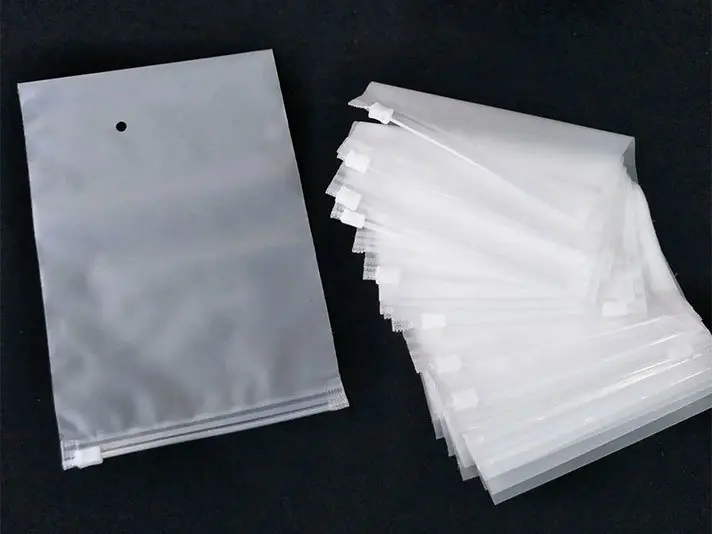

Suitable materials need to be selected before printing. According to the characteristics of the product and the usage environment, labels made of different materials such as paper, plastic, metal, etc. can be selected. At the same time, it is necessary to ensure that the material has good weather resistance and scratch resistance to ensure the durability of the label.

4、 Printing identification code

Print the generated QR code onto the label using a printing machine. During the printing process, it is necessary to strictly control the printing quality, ensure the clarity and resolution of the QR code, and avoid recognition problems during scanning. At the same time, it is necessary to add other information such as product name, production date, batch number, etc. to ensure the accuracy and clarity of the information.

5、 Label cutting and detection

Cut and adjust the printed labels according to the product size. Then, the labels are checked to ensure the integrity and accuracy of the QR code and other information. This step is a crucial step in ensuring product quality.

6、 Labeling and packaging

Attach the qualified labels to the product, ensuring that the labels are secure and not easily detached. Then, package the product to ensure its safety and integrity. During the labeling and packaging process, it is necessary to follow relevant operating procedures to ensure the correctness and aesthetics of the labels.

7、 Shipping and Delivery

Ship and distribute packaged products to ensure timely delivery to customers. During the shipping and distribution process, it is necessary to ensure the safety and integrity of the product, and avoid damage or loss during transportation.

中国

中国