What material is good for vacuum packaging bags?

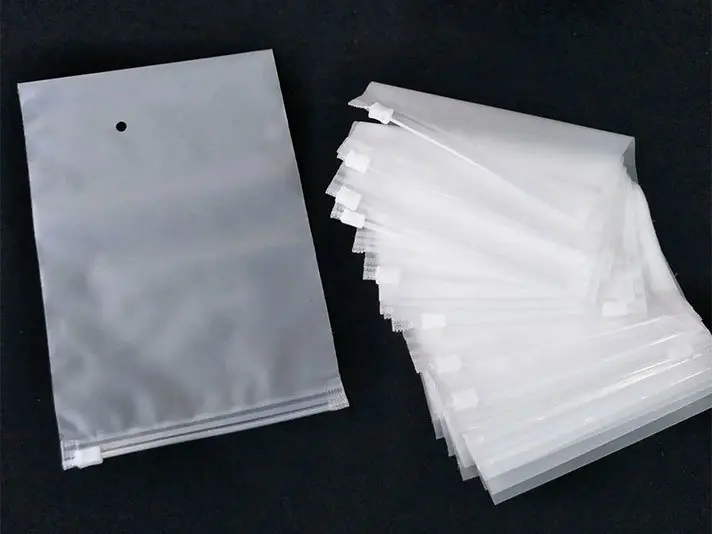

Vacuum packaging bags not only have the function of removing oxygen and ensuring quality, but also have the functions of pressure resistance, air barrier, and maintaining the original properties of the product. Vacuum bags can effectively maintain the original color, aroma, taste, shape, and nutritional value of food for a long time. The performance of vacuum packaging materials directly affects the storage life and taste changes of food. Choosing the right packaging materials is the key to the success of vacuum packaging. So, what material is good for vacuum packaging bags?

- Aluminum foil

Its material is generally PET/AL/CPE or PET/NY/AL/CPE. Among them, PET has good printing effect, NY has low oxygen permeability, AL has strong barrier properties and no light transmission, and CPE is the inner layer of the packaging. This product has good oxygen isolation, shielding, moisture resistance, light shielding functions, and excellent heat sealing properties. Aluminum foil vacuum bags are widely used in industries such as food, electronics, and chemicals. Due to the high cost of aluminum foil raw materials, the cost of vacuum is also relatively high.

- Co extrusion

Nylon co extruded bags are composed of PA, EVOH, PE, PP, TIE and other resins, and adopt a symmetrical or asymmetrical combination structure. Due to the addition of PA and EVOH, not only does it greatly improve the barrier properties of multi-layer films against oxygen and fragrance, composite peel strength, environmental resistance, and shelf life. Nylon co extruded bag is a multi-layer co extruded high barrier packaging material, and extrusion composite is a green and environmentally friendly production method for composite soft packaging. Borxu produces 7 or more extrusion machines for 7-layer nylon co extrusion, which melt and extrude different functional resin materials such as PA, PE, PP, TIE, EVOH, etc., and then merge them through their respective channels in a mold head. After blowing and forming, they are cooled and composite together. Co extruded high barrier packaging materials have the characteristics of high barrier, strong functionality, low cost, small capacity ratio, high strength, and flexible structure, which makes the production process of food packaging materials green and environmentally friendly.

- Nylon

The material used for nylon composite bags is similar to that of co extruded nylon. The main difference between PET/PE, PVC/PE, NY/PVDC, PE/PVDC, and PP/PVDC lies in the process. Composite bags are generally composed of substrate, laminating agent, barrier material, heat sealing material, printing and protective layer coating, etc. The commonly used composite film structure is: surface layer/adhesive layer 1/intermediate barrier layer/cat bonding layer 2/inner heat sealed layer. Nylon composite is laminated layer by layer through a laminating machine, and glue needs to be added in the middle.

The above introduction about the material of vacuum packaging bags is organized by Jinde Packaging, which provides one-stop services for vacuum packaging bag design, printing, lamination, slitting, and bag making. With over 10 years of rich experience accumulation, we can provide design solutions for users and offer a lot of technical support. Our hotline is 15902743510

中国

中国