Plastic Packaging Bag Transparent Laminated Vacuum Packaging Bag for Rice Bag

APPLICATION

Rice packaging bags have a wide range of applications, not only for the packaging and sales of rice producers, but also for the storage and use of rice in the family and catering industry.

Features

A. Made of moisture-proof and pest-proof materials, which can effectively protect rice from moisture and pests, and maintain the quality and nutritional value of rice.

B. Good sealing, which can effectively prevent air from entering the bag and prevent the rice from oxidizing and deteriorating.

C. The material is tough and durable, able to withstand friction and extrusion during transportation and storage, protecting the rice from external physical damage.

D. The lightweight design makes it easy to store and carry.

Key attributes

| Product Name | Rice packaging bag |

| Bag Type | Flat bottom bag or customized |

| Application | Packaging for rice |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | BOPET/AL/PE, BOPET/PE, MATOPP/VMCPP, BOPP/CPP, BOPP/PET/PE, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Zipper/handle top |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF, DDP etc |

Product advantages

● Jinde Packaging has advanced BOBST printing equipment, and the printed rice packaging bags are exquisite, ensuring quality.

● The rice packaging bags produced by Jinde Packaging are made of thickened materials, and we pay attention to the user experience, so the bag is sturdy and durable.

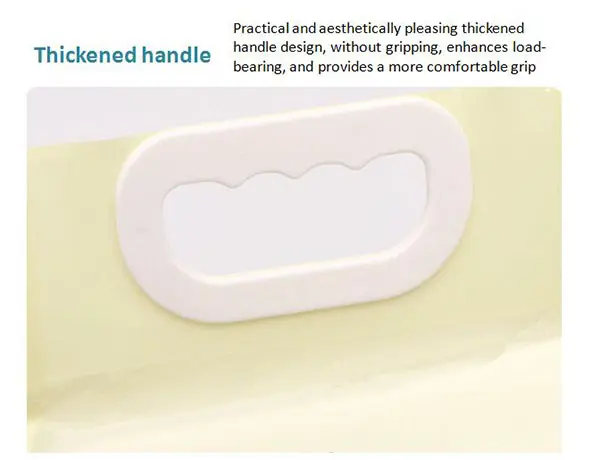

● The rice packaging bags produced by Jinde Packaging adopt a practical and beautiful thickened handle design, which does not hold hands and enhances load-bearing, making the grip more comfortable.

● The surface of the rice packaging bags produced by Jinde Packaging adopts a high-definition transparent window design, which provides a more intuitive and clear view of the products.

Product Encyclopedia

Plastic food-grade rice packaging bags are often used by people in daily life, its common characteristics are as follows:

1. Light in weight: This is a very important feature, according to the technical professional inspection, the relative density of plastic woven fabric is about 0.9-0.98 grams/cubic decimeter, the common food-grade rice bag raw material is PP, the relative density of PP is 0.9-0.91 grams/cubic decimeter.

2. High cracking strength: The raw material of plastic food-grade rice bags is a soft and high cracking strength raw material, which is related to its molecular formula, crystal level, yarn splitting trend.

3. Good wear resistance: The contradiction index between pure polyethylene plastic textiles is small, and only 0.12 or so, which is similar to polyester.

4. Good solvent corrosion resistance: Plastic food-grade rice bags have excellent corrosion resistance, and under normal conditions, food-grade rice bags can be stored for a long time.

5. Good electrical insulation: Pure polypropylene fabric is a good electrical insulation. Because it is not damp and will not be harmed by moisture in the air, the relative dielectric constant is 2.2-2.6, but the food-grade rice bag is not a complete insulation layer.

6. Environmental resistance: At normal temperature, plastic food-grade rice bags will not be eroded by water at all, and according to the measurement data information, its water absorption within 24 hours is less than 0.01%, and the water vapor penetration is also very low.

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国