Vacuum shrink packaging/ film/bags

APPLICATION

Vacuum shrink packaging/ film/bags are suitable for a variety of products that need to be kept fresh, moisture-proof, oxidation-proof and bacteria-proof, especially suitable for the food industry such as high temperature sterilized food, ham, curry, grilled eel, grilled fish and meat brine products.

Features

A. Antioxidant performance can effectively prevent oxygen from entering the inside of the package, thus prolonging the freshness period of the food.

B. Moisture-proof performance can block the entry of moisture and keep the original taste of food.

C. Prevent the growth of bacteria, mold and other microorganisms to ensure the hygiene and safety of food.

D. Good sealing performance and durability for long time storage and carrying.

Key attributes

Product Name |

Vacuum shrink packaging/ film/bags |

Bag Type |

Roll film/bags |

Application |

Packaging for high temperature sterilized food like ham, curry, grilled eel, grilled fish and meat brine products. |

Certificates |

ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

Surface Handling |

Gravure printing |

Material Structure |

BOPET/PE, BOPET/BOPA/PE, BOPET/AL/PE, BOPET/CPP, BOPA/CPP, BOPET/AL/CPP or Customized |

Samples |

Free sample or negotiated without freight paid |

Sealing&Handle |

heat-seal |

Size |

Customized |

Color |

Up to 10 colors |

Thickness |

15-200 microns |

MOQ |

10000PCS: mainly depends on the bag size and printing artwork |

Production Flow |

Film blowing-printing-lamination-slitting-bag making |

Terms of Payment |

T/T, L/C |

Lead Time |

15-30 days or as per negotiated |

Incoterms |

EXW, FOB, CFR, CIF |

Product advantages

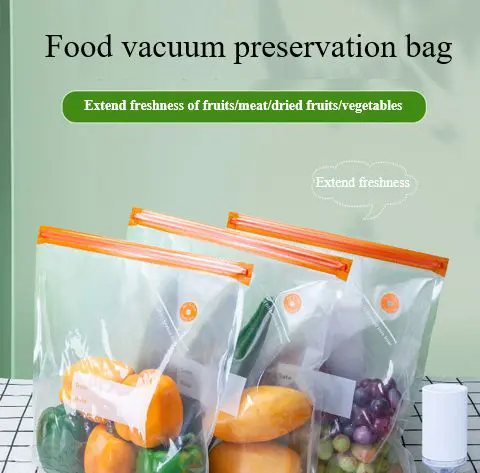

● Food vacuum preservation bags produced by Jinde Packaging can extend the preservation of fruits, meat, dried fruits, vegetables, etc

● Our vacuum packaging bags have the characteristics of cold resistance, heat resistance, recyclability, orderly packaging, and extended freshness.

● The food vacuum preservation bags produced by Jinde Packaging Company have the characteristics of strong sealing and non leakage holding. We have specially upgraded and thickened the shut-off valve, and adopted double sealing strips, so that the vacuum preservation bags can quickly extract air and are not prone to leakage.

● We have specially designed writable labels for each vacuum packaging bag, making it convenient for you to record at any time and ensuring long-lasting preservation of delicious food.

Product Encyclopedia

A.Technical Overview

The main role of the vacuum bag is to remove oxygen, in order to help prevent food spoilage, the principle is relatively simple, because the food mold deterioration caused mainly by microbial activities, and most microorganisms (such as mold and yeast) survival is the need for oxygen, and vacuum packaging is to use this principle, the bag and the food cell oxygen pumped off, so that the micro-objects to lose the "survival of the environment". environment". Experiments have proved that: when the oxygen concentration in the bag ≤ 1%, the growth and reproduction rate of micro-organisms will drop sharply, oxygen concentration ≤ 0.5%, most micro-organisms will be inhibited and stop reproducing.

B. Main Material

PE is suitable for low-temperature use, RCPP is suitable for high-temperature cooking;

PA is to increase physical strength and puncture resistance;

AL aluminum foil is to increase the barrier performance, shading;

PET is to increase mechanical strength and excellent stiffness.

C. Composite types

Generally, it is two-layer, PA/PE or PA/RCPP, PET/PE or PET/RCPP.

There are also three-layer and four-layer, in order to increase the material texture performance:

PET/PA/PE

PET/AL/RCPP

PA/AL/RCPP

PET/PA/ AL/RCPP

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample for free charge but the cost of freight is on buyer account.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国